Product display

Cylindrical mirror coating

Classification:

Key words:

Cylindrical mirror coating

E-mail:

- Product Introduction

- Product Parameters

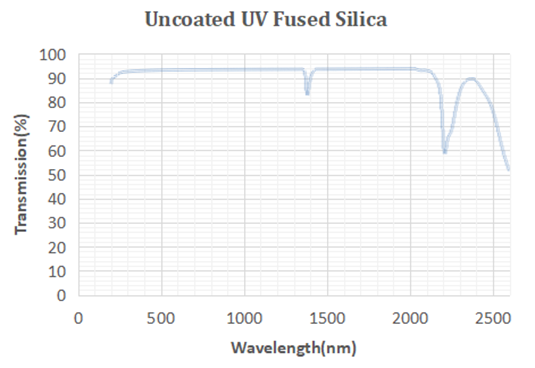

- Transmittance

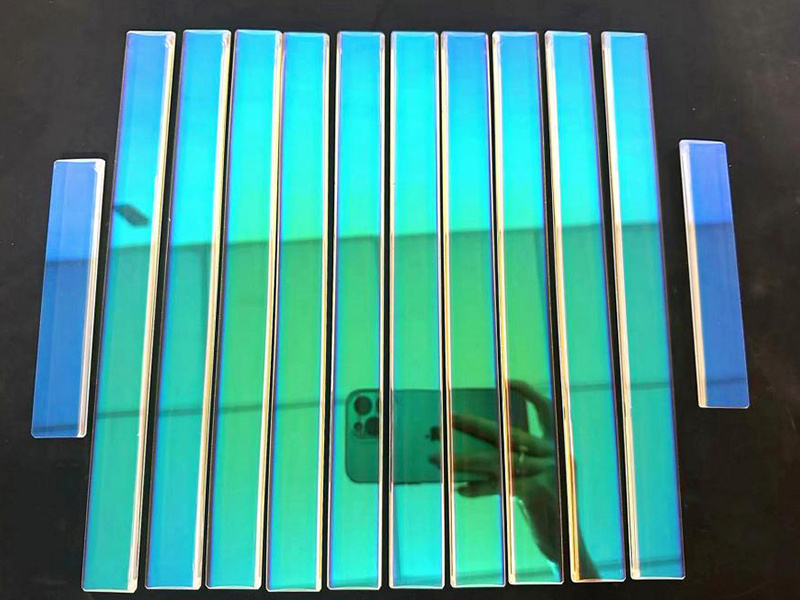

- Product Picture

- Processing technology

- Optical use

- Custom Specifications

- Technical Answers

-

- Commodity name: Cylindrical mirror coating

The quartz cylindrical lens is a cylindrical lens made of fused silica. Fused silica is an amorphous (glassy) state of silicon oxide (quartz, silica) with long-range disorder in its atomic structure. Such lenses provide high service temperatures and low coefficients of thermal expansion through three-dimensional structural cross-links. The main design purpose of the cylindrical lens is to change the image size. For example, a point light spot is converted into a line spot, or the height of the image is changed without changing the image width. Its focal length can be negative or positive, suitable for laser line generation or anamorphic beam shaping to cyclize the laser output.

A quartz cylindrical lens is an amorphous (glassy) lens made of fused silica (SiO2). Fused silica is a typical glass whose atomic structure is long-range disordered. Such a lens provides its high service temperature and low coefficient of thermal expansion through a three-dimensional structural cross-link. There are two structures, plane-concave and plane-convex, which are used to diverge or converge the beam, respectively. One characteristic of such lenses is that incident light rays can be focused in a certain dimension and stretch the image. Its focal length can be negative or positive, suitable for laser line generation or anamorphic beam shaping to cyclize the laser output.

This kind of lens material K9, ultraviolet fused silica, CaF2, ZNSE, etc., are optional. All materials can be selected without coating or coating antireflection coating. In addition, fused Shi Ying cylindrical lens has four major processes: rubber disc polishing, high-speed polishing, ring polishing and CNC polishing, and has ZYGO, AFM, reflection and transmission eccentricometer, 15-second goniometer, ultraviolet gluing centering system, non-contact laser thickness gauge, 2D imager and spherometer and other process equipment, which can ensure the accuracy of data.

-

Diameter/Size (mm) Focal length (mm) Thickness (mm) Radius of curvature (mm) Design Wavelength 10 × 10 25 3.15 11.45 587.6nm 12.5 50 2.87 22.93 587.6nm 20 x 10 50 2.55 22.92 587.6nm 25 75 4.35 34.39 587.6nm 30 x 20 75 3.49 34.35 587.6nm Material Data Sheet Material Data

optical characteristic Optical Properties

Transmission Range through Range

0.18-2.1μm

Refractive index Refractive index@0.5876 μm

1.4585

Physical characteristics Physical Properties

Density Density[g/cm3]

2.21

熔点Melting Point[deg C]

1900

热导率ThermalConductivity[W/(m×deg C)]

1.35

Thermal expansion coefficient Thermal Expansion [deg C- 1]

4.0*10-6

比热容Specific Heat Capacity[J/(Kg*deg C ]

0.728*10-3

Young's Modulus Young's Modulus[GPa]

7.36

Shear Modulus Shear Modulus[GPa]

3.14

Poisson coefficient Poisson Coefficient

0.17

Chemical characteristics Chemical Properties

solubility Solubility

Insoluble

-

-

-

The information is being sorted out......

-

Use

Related industries

Imaging

Optical instrument manufacturing, microscope manufacturing, etc.

single direction beam collimation

Laser applications, optical communications, etc.

beam shaping

Laser applications, optical communications, etc.

-

The information is being sorted out......

-

What is quartz?

Quartz, or Fused silica, is an amorphous (glassy state) of silicon oxide (quartz, silica). It is a typical glass whose atomic structure is long-range disordered. Its high service temperature and low coefficient of thermal expansion are provided by three-dimensional structural cross-links. Usually with high purity, its purity is better than other types of glass. Its manufacture is usually made by melting quartz crystals at high temperatures. Fused silica is widely used in telecommunications, optical instruments, semiconductor and electronic industries due to its excellent optical, thermal and mechanical properties.The performance parameters of quartz glass?

1. Refractive index: The refractive index is very high, and it has high transmittance in the ultraviolet band, visible light and near-infrared band. Its refractive index is between 1.45 and 1.47, which is the highest among common optical glasses.

2. Thermal expansion coefficient: The thermal expansion coefficient is low, and its linear expansion coefficient is 0.55 × 10 ^-6/℃ between 20 ℃ and 300 ℃. This low coefficient of expansion makes the quartz glass excellent in both the holding strength and the stability at high temperatures.

3. Chemical stability: It has excellent chemical stability, and its stability in chemically corrosive substances such as acids, bases and solvents is excellent. Due to this characteristic, fused silica glass is widely used in the fields of semiconductors, biomedicine and semiconductor processing.

4, mechanical properties: high hardness and good toughness, can withstand greater pressure and impact.quartz manufacturing method?

1. Raw material processing: natural quartz sand is processed by crushing, screening, washing and other processes to obtain raw materials with high purity and stability.

2. Smelting: Inductive heating or gas/oxygen flame heating is used to melt the quartz material. In order to obtain highly pure fused silica raw materials, the smelting process needs to be treated by filtration, degassing and de-ashing.

3, molding: fused quartz raw materials through molding, grinding, temperature treatment and other process steps, and finally made of various shapes and specifications of fused quartz products.The refractive index of quartz?

1.46Quartz use?

1. Optical fiber manufacturing: The key raw material for optical fiber used in telecommunications, its strength and high melting point make it an ideal material in optical fiber manufacturing.

2. Halogen lamps and high-intensity discharge lamps: Due to their high heat resistance and low expansion coefficient, they are used as housings for halogen lamps and high-intensity discharge lamps. They must work at higher housing temperatures to achieve high brightness and long life. Combination.

Chemical industry: Due to its chemical inertness and good corrosion resistance, it is also widely used in the chemical industry.

4, semiconductor and electronic industry: due to its high heat resistance and low expansion coefficient, can be used in the semiconductor manufacturing process of high temperature reaction chamber, photomask, crystal growth chamber and other parts of the manufacturing, but also can be used to manufacture high-precision optical components, semiconductor chip manufacturing equipment.

5. Deep diving utensils: Because of its strength and high temperature resistance, it is used for deep diving utensils, such as floating balls and chassis mirrors.What is a cylindrical lens?

It is a cylindrical lens with a cross-section of two arcs or a circular arc straight line, divided into biconvex, biconvex, plano-convex, plano-concave and crescent. It has two refracting spheres and is the simplest coaxial spherical system in the optical system. The cylindrical lens has a focal line parallel to the surface of the cylinder, and the distance between the focal line and the cylinder depends on the radius of curvature of the mirror and the refractive index of the glass.Cylindrical lens meridian?

It refers to a line perpendicular to the cylinder axis (I. e., the axis of symmetry of the lens). In a cylindrical lens, no change in vergence occurs when light passes through a meridian.cylindrical lens imaging characteristics

It is the distance at which the rays parallel to the axis of the lens converge at a point after passing through the lens. Unlike a spherical lens, the focal length of a cylindrical lens is not only related to the radius of curvature, but also to its axial length. Therefore, the focal length of a cylindrical lens is usually expressed in a functional form.

The curvature of a cylindrical lens refers to the degree of curvature of the lens surface. For a cylindrical lens, the curvature is the same, but the radius of curvature is different. The smaller the radius of curvature, the greater the degree of curvature of the lens, and the stronger the focusing ability.

A cylindrical lens is generally a lens used to focus incident light onto a line or to change the aspect ratio of an image. It is usually imaged linearly and can control the direction of the beam. A cylindrical lens has a cylindrical surface that allows incoming light to focus in a certain dimension and stretch the image. The focal length of the cylindrical mirror can be negative or positive, suitable for laser line generation or anamorphic beam shaping. For example, a point light spot is converted into a line spot, or the height of the image is changed without changing the image width. In addition, the material of the cylindrical lens is usually made of a transparent material such as optical glass or optical plastic, which has the advantages of high light transmittance, high refractive index and stability.

online message

Related Products