Product display

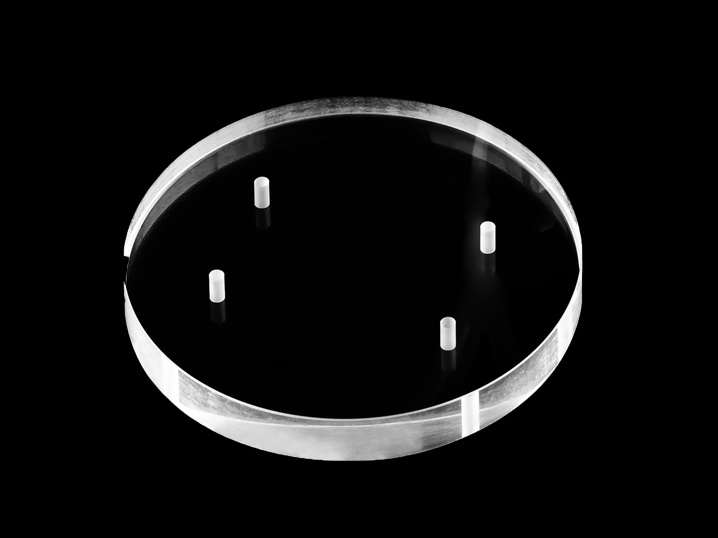

Circular window

Classification:

Key words:

Circular window

E-mail:

- Product Introduction

- Product Parameters

- Transmittance

- Product Picture

- Processing technology

- Optical use

- Custom Specifications

- Technical Answers

-

- Commodity name: Circular window

Circular window

Fused silica circular window is a kind of optical element made of fused silica. It has excellent optical properties and is widely used in aerospace, military, medical, scientific research and other fields.

This window is usually used as a protective window for electronic sensors or detectors of the external environment, and is used to separate the environment on both sides, such as separating the inside and outside of the instrument, so that the inside and outside of the instrument are isolated from each other, thereby protecting internal devices. It does not change the magnification of the system.

Fused silica is a colorless and transparent material with high purity and high temperature melting. It has excellent optical properties such as high transmittance, low refractive index, low dispersion, high thermal stability and low thermal expansion coefficient. Fused silica window as one of the commonly used optical components.

Material Data Sheet Material Data

optical characteristic Optical Properties Transmission Range through Range 0.18-2.1μm Refractive index Refractive index@0.5876 μm 1.4585 Physical characteristics Physical Properties Density Density[g/cm3] 2.21 熔点Melting Point[deg C] 1900 热导率ThermalConductivity[W/(m×deg C)] 1.35 Thermal expansion coefficient Thermal Expansion [deg C- 1] 4.0*10-6 比热容Specific Heat Capacity[J/(Kg*deg C] 0.728*10-3 Young's Modulus Young's Modulus[GPa] 7.36 Shear Modulus Shear Modulus[GPa] 3.14 Poisson coefficient Poisson Coefficient 0.17 Chemical characteristics Chemical Properties solubility Solubility Insoluble -

Diameter (mm) Thickness (mm) Parallelism Finish PV through aperture 5 1 60-40 λ/2 3 ′ >90% 12.7 2 60-40 λ/2 3 ′ >90% 25.4 2 60-40 λ/2 3 ′ >90% 38.1 3 60-40 λ/2 3 ′ >90% 50.8 3 60-40 1λ 3 ′ >90% 50.8 4 60-40 1λ 3 ′ >90% 75 5 60-40 1λ 3 ′ >90% 76.2 6.3 60-40 λ/2 3 ′ >90% -

-

-

The information is being sorted out......

-

Use

Related industries

optical instrument

telescope, microscope, sight, etc

laser system

Laser, laser radar, etc.

infrared optical system

Infrared detection, infrared imaging, etc.

-

Diameter range

2-300mm

Thickness

0.12-60mm

Finish

80-50,60-40,40-20,20-10,10-5

Face type

Λ/2,λ/4,λ/8,λ/10

Parallelism

<3'-30”

through aperture

>90%

Coating

Customizable

-

What is Fused Quartz?

Fused silica, or Fused silica, is an amorphous (glassy state) of silicon oxide (quartz, silica). It is a typical glass whose atomic structure is long-range disordered. Its high service temperature and low coefficient of thermal expansion are provided by three-dimensional structural cross-links. Usually with high purity, its purity is better than other types of glass. Its manufacture is usually made by melting quartz crystals at high temperatures. Fused silica is widely used in telecommunications, optical instruments, semiconductor and electronic industries due to its excellent optical, thermal and mechanical properties.Performance parameters of fused silica glass

1. Refractive index: The refractive index is very high, and it has high transmittance in the ultraviolet band, visible light and near-infrared band. Its refractive index is between 1.45 and 1.47, which is the highest among common optical glasses.

2. Thermal expansion coefficient: The thermal expansion coefficient is low, and its linear expansion coefficient is 0.55 × 10 ^-6/℃ between 20 ℃ and 300 ℃. This low coefficient of expansion makes the quartz glass excellent in both the holding strength and the stability at high temperatures.

3. Chemical stability: It has excellent chemical stability, and its stability in chemically corrosive substances such as acids, bases and solvents is excellent. Due to this characteristic, fused silica glass is widely used in the fields of semiconductors, biomedicine and semiconductor processing.

4, mechanical properties: high hardness and good toughness, can withstand greater pressure and impact.Manufacturing method of fused silica

1. Raw material processing: natural quartz sand is processed by crushing, screening, washing and other processes to obtain raw materials with high purity and stability.

2. Smelting: Inductive heating or gas/oxygen flame heating is used to melt the quartz material. In order to obtain highly pure fused silica raw materials, the smelting process needs to be treated by filtration, degassing and de-ashing.

3, molding: fused quartz raw materials through molding, grinding, temperature treatment and other process steps, and finally made of various shapes and specifications of fused quartz products.Refractive index of fused silica

1.46The role of the window

Separate the environment on both sides, such as the inside and outside of the instrument, so that the inside and outside of the instrument are isolated from each other, thereby protecting the internal devices. In particular, it can be used as a protective window for electronic sensors or detectors of the external environment.

Previous Page

Next Page

Previous Page

Next Page

online message

Related Products